Lithium batteries are a type of battery that uses lithium metal or lithium alloy as positive/negative electrode materials and non-aqueous electrolyte solutions. They are an important component of the world's clean energy. The production process of lithium batteries is divided into three stages: front, middle, and back. The purpose of the front stage is to process the raw materials into pole pieces, and the core process is coating; the purpose of the middle stage is to process the pole pieces into unactivated cells; the back stage is testing and packaging, and the core processes are formation and capacity separation. The production process of lithium batteries is long, and many processes are involved in the production process. Each process will affect the product performance of lithium batteries. Among them, dust, moisture, and metal particles are the three key factors that must be strictly controlled in the production process of lithium batteries.

Mixing ingredients

Positive electrode coating

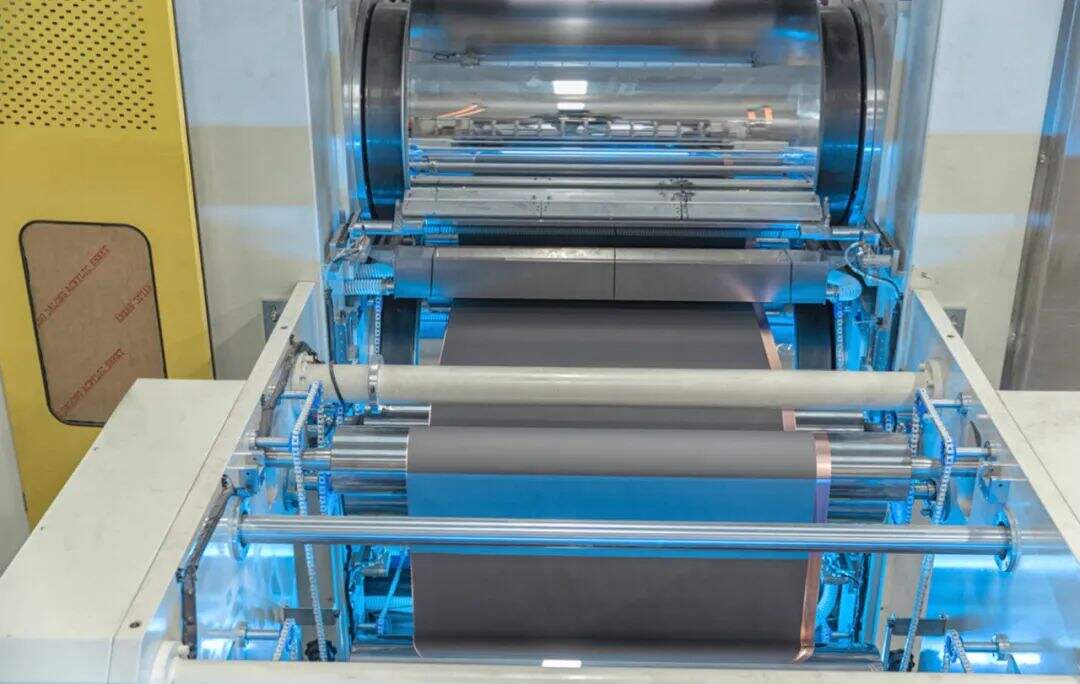

Negative electrode rolling

From the dust removal aspect, if the dust, smoke, welding slag, debris, etc. generated in the production process enter the battery through the pole piece, diaphragm or cover plate, it will have a great impact on the battery, such as causing high self-discharge of lithium-ion batteries, internal short circuit of lithium-ion batteries, battery fire and explosion, etc.

Processes that generate dust or smoke

Mixing, rolling and pre-slitting, slitting, winding, die-cutting, lamination, plasma cleaning, welding, etc.

The dust generated by different lithium battery manufacturing processes is different. Most of the dust generated in the production process is flammable and explosive. Therefore, when removing dust from various processes of lithium batteries, the flammable and explosive properties of the dust must be fully considered.

Imported nano flame retardant antistatic filter material RHZ-W-FR-AS

RHZ-W-FR-AS nano flame retardant antistatic filter material, a new product developed by Jiangsu Renhe Environmental Protection and European filter material manufacturers! This filter material has very uniform, continuous, elastic fibers, forming a mesh structure with a small diameter. This nanofiber "net" is built on a composite fiber substrate with antistatic and flame retardant properties, which can capture fine dust on the surface, even submicron dust, and has antistatic and flame retardant properties at the same time, which can provide effective early preventive measures in explosion-proof conditions.

Advantages of imported nano flame retardant antistatic filter media:

Improves the efficiency of Filter Cartridge filtration and can achieve lower emission standards.

• Fine fiber technology ensures a longer service life of the filter, reduces the number of filter cartridge replacements and reduces maintenance costs.

• Has lower initial resistance than polyester fiber, PTFE coated filter media, etc.

• Excellent water resistance, suitable for some special working conditions.

• Has excellent cleaning performance.

• Surface filtration principle makes it difficult for dust to remain in the substrate.

• Lower cleaning air pressure saves more energy.

• Has flame retardant function, can play a non-combustible characteristic in working conditions with fire sources.

• Has anti-static function, can be used in working conditions that require anti-static and explosion-proof.

• In addition, metal parts made of stainless steel can be provided.

Hot News

Hot News2025-01-17

2025-01-13

2025-01-08

2024-12-27

2024-12-23

2024-12-16